Minimum Slope for Metal Roof in Florida: Complete 2026 Code Guide

Posted 1.07.2026 | 6 Minute Read

Thinking about installing a metal roof on your Florida home but worried about your roof’s slope? You’re not alone. Many homeowners wonder if their low-slope or flat roof can support a metal roofing system, especially with Florida’s intense weather patterns.

The minimum slope for metal roofs in Florida varies by system type. Standing seam metal roofs require just 1/4:12 slope (2% grade), while exposed fastener systems need 3:12 slope (25% grade). These requirements come directly from the Florida Building Code and ensure your roof performs properly during heavy rains and hurricane conditions.

Quick Answer: Standing seam metal roofs can be installed on slopes as low as 1/4 inch per foot, making them suitable for most flat roof applications in Florida.

Let’s explore exactly what these numbers mean for your roofing project and how you can make metal roofing work on almost any slope.

Understanding roof slope basics

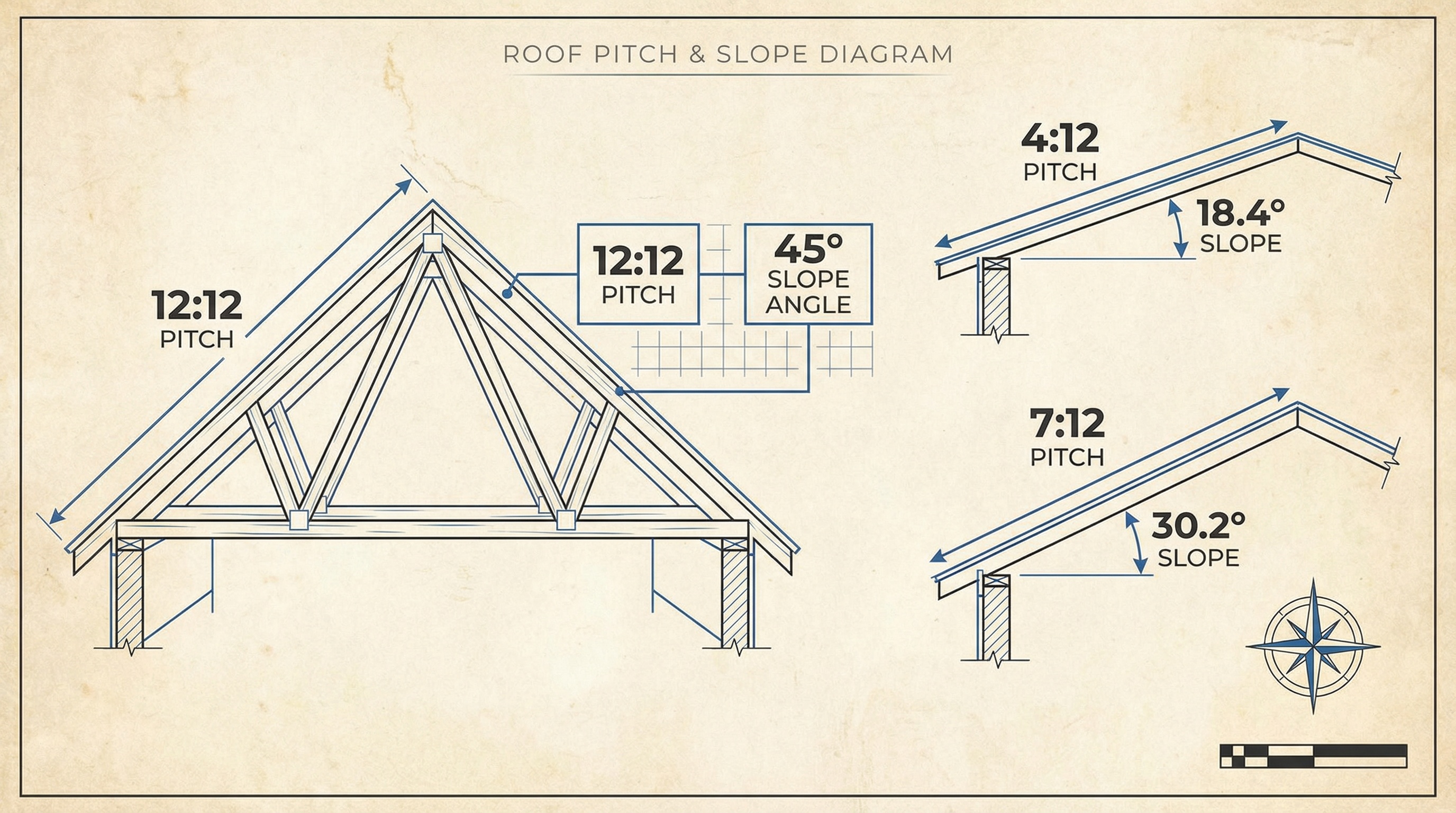

Roof slope, also called pitch, measures how steep your roof is. It’s expressed as a ratio showing vertical rise over horizontal run. For example, a 4:12 slope means your roof rises 4 inches for every 12 inches it extends horizontally.

In Florida, many homes have mixed slopes. Your main roof might have a 4:12 pitch perfect for shingles, while a garage or addition could have a 1:12 low-slope section. These flatter areas often use TPO or modified bitumen, but metal roofing for flat roofs can be an excellent upgrade option.

The slope affects how quickly water drains off your roof. Steeper slopes shed water faster, while flatter roofs need materials designed to handle slower drainage. This is why different roofing materials have different minimum slope requirements.

Florida Building Code requirements by metal roof type

According to Florida Building Code Section 1507.4.2, metal roof minimum slopes depend on the specific system you choose:

| Metal Roof Type | Minimum Slope | Percentage Grade | Special Requirements |

|---|---|---|---|

| Standing seam | 1/4:12 | 2% | Must be mechanically seamed |

| Exposed fastener | 3:12 | 25% | No exceptions allowed |

| Snap-lock panels | 2:12 | 17% | Product-specific requirements |

Standing seam systems offer the most flexibility for low-slope applications. These panels lock together mechanically and can handle ponding water better than other metal roofing types. However, proper installation with quality sealants is crucial for performance.

Exposed fastener systems, while more affordable, require steeper slopes because water can penetrate around the screws on flatter roofs. The 3:12 minimum helps ensure water flows off quickly before it can work its way under the panels. To understand the differences between these systems, check out our comparison of standing seam vs. 5V metal roofing.

Important Note: High-Velocity Hurricane Zones (Broward and Miami-Dade counties) have additional requirements that may affect minimum slopes for certain applications.

Solutions for increasing roof slope

If your existing roof doesn’t meet the minimum slope requirements, you have several options to make metal roofing work. The most common solution involves adding tapered insulation or foam boards beneath the new roofing system.

Tapered insulation serves double duty by increasing your roof’s slope while improving energy efficiency. This approach typically costs less than structural modifications and can often bring a roof from 1/8:12 up to the required 1/4:12 for standing seam installation.

Another option is installing crickets or tapered sections in specific areas where water tends to pond. Your roofing contractor can assess your current slope and recommend the most cost-effective approach for your situation.

Some homeowners choose to modify the roof structure itself, but this involves more extensive work and higher costs. This approach makes sense when you’re already doing major renovations or if the existing roof has structural issues. If you’re considering putting a metal roof over shingles, you’ll need to account for how this affects your overall slope.

Cost considerations and material selection

Metal roofing costs vary significantly based on the system type and slope requirements. Exposed fastener systems typically cost $7 to $12 per square foot, while standing seam systems range from $15 to $25 per square foot.

For low-slope applications, standing seam often provides better long-term value despite the higher upfront cost. These systems last longer, require less maintenance, and perform better in Florida’s challenging weather conditions. For detailed pricing information, explore our guide on average metal roof cost per square foot in Florida.

When calculating costs, factor in any slope modifications needed. Adding tapered insulation might increase your project cost by $2 to $4 per square foot, but this investment pays off through improved drainage and energy savings.

Cost Tip: Getting multiple quotes helps you understand the true cost difference between making your existing slope work versus upgrading to a steeper pitch.

Remember that proper installation matters more than the specific product you choose. Work with contractors experienced in Florida metal roofing who understand local code requirements and weather challenges. Before making your final decision, review the comprehensive pros and cons of metal roofs in Florida to ensure this roofing type fits your needs.

Whether you’re dealing with a completely flat roof or just need to meet minimum slope requirements, metal roofing can work for most Florida homes. The key is choosing the right system for your specific slope and ensuring proper installation that meets both code requirements and manufacturer specifications. With the right approach, you can enjoy the durability and energy efficiency of metal roofing regardless of your roof’s current pitch.