Best Roof Underlayment for Florida Homes: Synthetic vs Peel and Stick vs Felt

Posted 1.07.2026 | 7 Minute Read

When you’re planning a roof replacement in Florida, choosing the right underlayment can mean the difference between a roof that lasts decades and one that fails during the next hurricane season. Your roof underlayment acts as your home’s second line of defense against water intrusion, and in a state where wind-driven rain and extreme weather are facts of life, this choice matters more than you might think.

Synthetic underlayment is currently the top choice for Florida homes, offering 25-50 year lifespans and superior water resistance compared to traditional felt, which typically lasts only 10 years. According to the Florida Building Code, all roofs must include approved underlayment such as #30 felt, synthetic sheets, or self-adhered membranes, with additional requirements in High-Velocity Hurricane Zones.

Let’s walk through your three main options so you can make an informed decision that protects your investment and keeps your family safe.

Quick Fact: In Florida’s High-Velocity Hurricane Zones like Miami-Dade and Broward counties, self-adhered underlayment meeting ASTM D1970 standards is mandatory, not optional.

What is roof underlayment and why does it matter in Florida

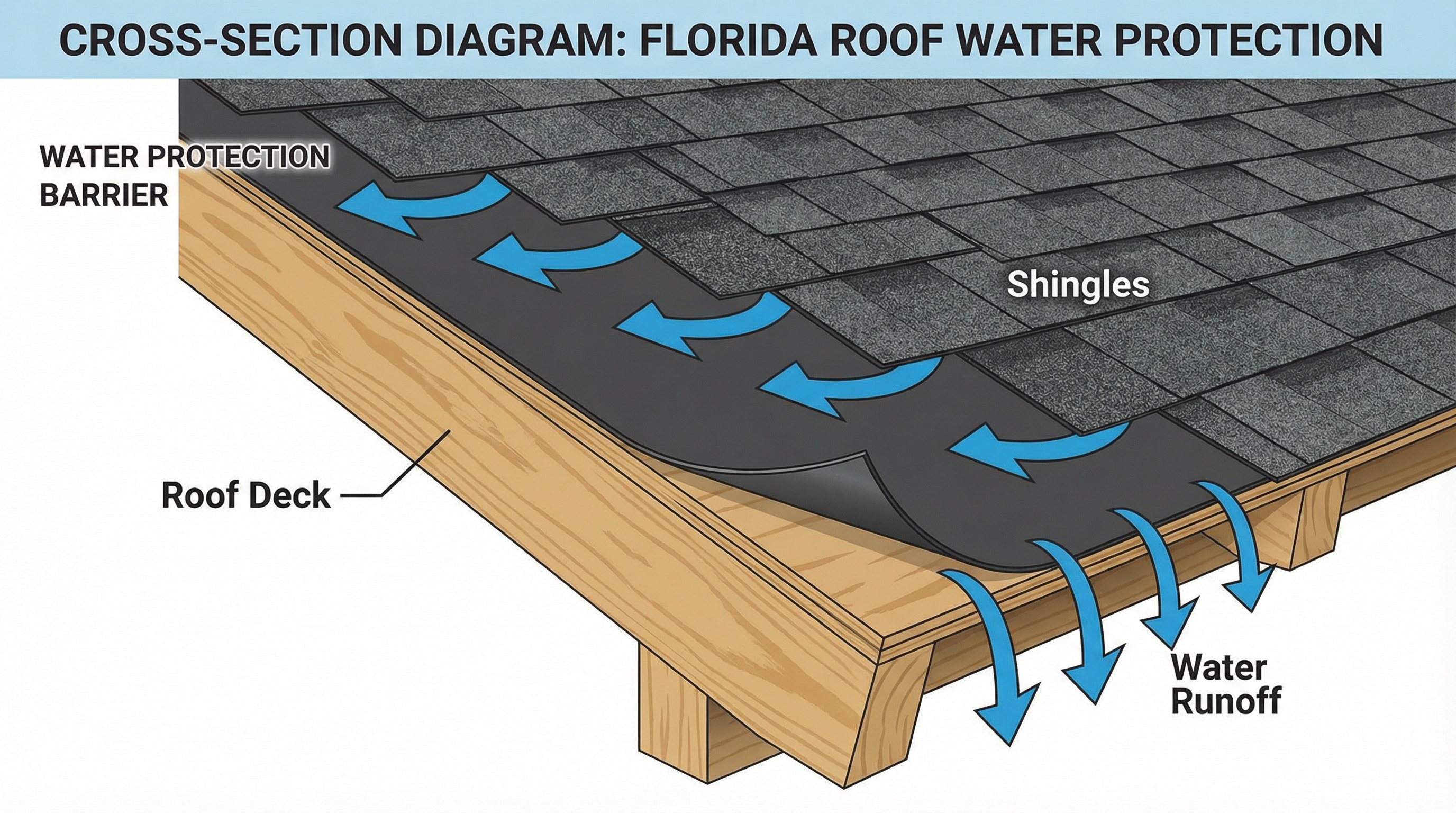

Think of roof underlayment as your roof’s insurance policy. It’s a water-resistant barrier installed directly on your roof deck, underneath your shingles or tiles. While your outer roofing material handles most of the weather, underlayment catches any water that sneaks through and directs it away from your home’s structure.

In Florida’s challenging climate, this protection becomes critical. Our state faces unique threats that make quality underlayment essential. Hurricane-force winds can drive rain horizontally under shingles. Intense heat can cause roofing materials to expand and contract, creating gaps. High humidity promotes mold growth if moisture gets trapped.

Your underlayment also provides secondary benefits like improved insulation and noise reduction during storms. For metal roofs especially, good underlayment can significantly reduce the drumming sound during heavy rain.

The steadfastroofingfl.com experts emphasize that proper underlayment selection and installation is just as important as choosing the right roofing material itself, particularly given Florida’s stringent building codes. Understanding what is considered an old roof in Florida can also help you determine if it’s time to upgrade your underlayment along with your roofing materials.

Synthetic underlayment: The modern choice for Florida homes

Synthetic underlayment has become the go-to choice for most Florida roofing projects, and there are solid reasons why. Made from woven polyethylene or polypropylene fibers, this engineered material outperforms traditional options in almost every category that matters for our climate.

The biggest advantage is durability. While felt underlayment might last 10 years, synthetic options routinely provide 25-50 years of protection. They won’t absorb water like felt does, eliminating the risk of rot and mold growth against your roof deck. This waterproof quality makes synthetic underlayment ideal for Florida’s humid conditions.

Installation benefits matter too. Synthetic underlayment is lightweight, making it easier and safer for roofers to handle. Most products feature slip-resistant surfaces, reducing accident risk during installation. They can typically withstand UV exposure for 6+ months without degrading, which is crucial during Florida’s unpredictable weather patterns that might delay roofing projects.

The main drawback is cost. Synthetic underlayment costs more upfront than felt, though the longer lifespan often makes it more economical over time. Quality varies significantly between manufacturers, so working with experienced contractors who know which products perform best in Florida conditions is essential.

Pro Tip: Look for synthetic underlayments with Florida Product Approval numbers when planning your roof replacement to ensure code compliance.

Peel and stick (rubberized asphalt): Maximum water protection

Peel and stick underlayment, technically called rubberized asphalt or self-adhered membrane, offers the highest level of water protection available. This material combines tough asphalt with waterproof rubber backing that adheres directly to your roof deck, creating a sealed barrier that’s virtually impenetrable to water.

In Florida’s High-Velocity Hurricane Zones, peel and stick isn’t just recommended – it’s required by code. The southshorecontractorstampa.com team notes that these products must meet ASTM D1970 standards and create sealed roof decks that can withstand extreme wind-driven rain.

The installation process is straightforward but permanent. The adhesive backing bonds so strongly to roof decking that removal becomes extremely difficult. This creates excellent protection but can complicate future roof replacements, potentially requiring deck replacement in some areas. When considering the differences between new construction roofing vs. roof replacement, the underlayment choice becomes even more critical since replacement projects must work with existing deck conditions.

Performance-wise, peel and stick excels in water resistance and can provide 30+ years of service life. The thick material also offers superior insulation properties, helping reduce cooling costs during Florida’s hot summers. However, it’s the most expensive underlayment option and requires skilled installation to avoid problems like trapped air bubbles or improper sealing.

Felt underlayment: Why it’s becoming obsolete

Traditional felt underlayment, once the industry standard, has largely fallen out of favor for Florida applications. Made from organic or fiberglass mat saturated with asphalt, felt provides basic water resistance but comes with significant limitations in our climate.

The primary issue is water absorption. Unlike synthetic or peel and stick options, felt actually absorbs moisture over time. In Florida’s humid environment, this can lead to mold growth, deck rot, and premature failure. Felt also degrades quickly under UV exposure, making it problematic if installation gets delayed by weather.

| Underlayment Type | Lifespan | Water Resistance | UV Tolerance | Cost |

|---|---|---|---|---|

| Synthetic | 25-50 years | Excellent | 6+ months | Higher |

| Peel & Stick | 30+ years | Superior | Varies | Highest |

| Felt | 10 years | Good | 30-90 days | Lowest |

Weight is another concern. Felt underlayment is significantly heavier than synthetic alternatives, adding unnecessary load to your roof structure. During installation, felt tears easily and becomes even heavier when wet, creating safety and performance issues. When comparing plywood vs OSB for your roof replacement, the underlayment choice should complement your decking material selection for optimal performance.

While #30 felt remains code-compliant in many Florida areas, most reputable contractors now recommend against it except in very specific budget-constrained situations. The castleroofingandconstruction.org professionals point out that the small upfront savings rarely justify the long-term risks and shorter lifespan.

Important Note: Some manufacturers require synthetic underlayment for warranty coverage, making felt a poor choice even when code-compliant.

Choosing the right underlayment for your Florida home depends on your specific situation, but the trend is clear. Synthetic underlayment offers the best balance of performance, durability, and value for most applications. Peel and stick provides maximum protection in hurricane zones or high-risk areas. Felt, while still available, rarely makes sense given the superior alternatives now available.

Remember that proper installation matters as much as material choice. Work with licensed Florida roofing contractors who understand local building codes and have experience with your chosen underlayment type. Whether you’re working on a coastal property requiring specialized roofing services or dealing with issues like chimney flashing repairs that require underlayment attention, your roof is too important to leave to chance, especially in a state where weather can change everything in a matter of hours.