TPO vs EPDM Rubber Roofing 2026: Complete Florida Comparison Guide

Posted 1.07.2026 | 7 Minute Read

Choosing between TPO and EPDM rubber roofing for your Florida flat roof can save you thousands in energy costs and repairs over the next 20 years. Both materials offer excellent protection against Florida’s intense UV rays, heavy rainfall, and hurricane conditions, but each has distinct advantages depending on your specific needs.

TPO (Thermoplastic Polyolefin) typically costs $10-20 per square foot and lasts 20-25 years, while EPDM (Ethylene Propylene Diene Monomer) runs $12-26 per square foot with a lifespan of up to 30 years. The key differences lie in energy efficiency, maintenance requirements, and installation methods.

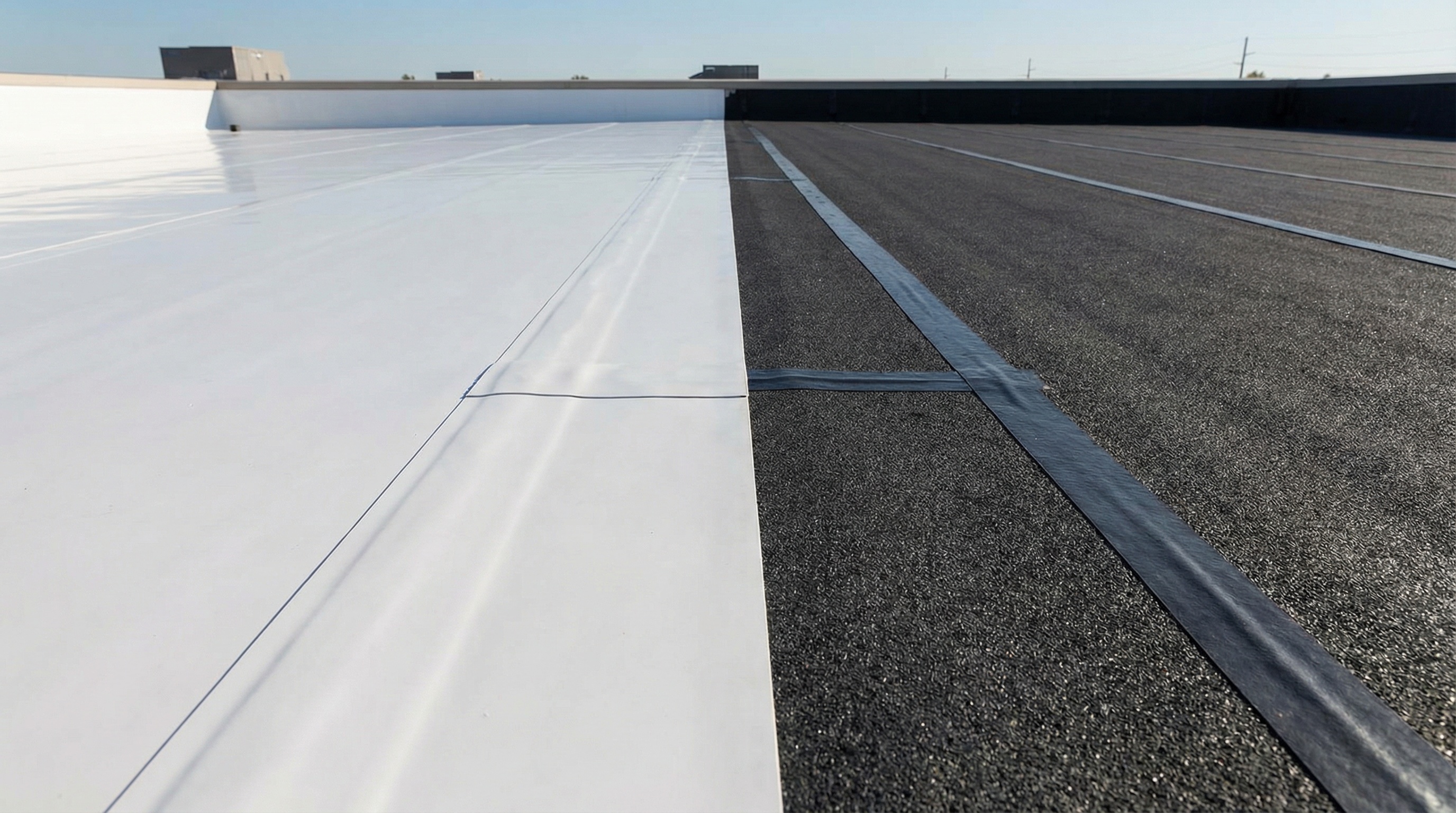

Quick Answer: TPO offers better energy savings with its reflective white surface, while EPDM provides superior longevity and flexibility in extreme weather conditions. Your choice depends on budget, building type, and long-term energy goals.

Understanding these rubber roofing options helps you make an informed decision that protects your investment and keeps your building comfortable year-round.

Understanding TPO and EPDM rubber roofing materials

TPO roofing consists of a single-ply membrane made from blended polymers, including ethylene-propylene rubber and polypropylene. This combination creates a flexible, heat-resistant material that comes primarily in white, though gray and tan options are available. The material’s reflective properties make it particularly effective in Florida’s hot climate.

EPDM roofing uses synthetic rubber made from ethylene propylene diene monomer. Available in both black and white versions, EPDM has been a trusted flat roofing solution for over 50 years. The material maintains flexibility even in extreme temperatures, making it ideal for regions that experience both intense heat and occasional cold snaps.

Both materials qualify as single-ply roofing systems, meaning they provide protection through one continuous membrane rather than multiple layers. This design reduces potential failure points while simplifying installation and maintenance procedures. When evaluating the best types of flat roofing materials for Florida, TPO and EPDM consistently rank among the top choices for commercial and residential applications.

The manufacturing processes differ significantly between these materials. TPO undergoes heat-welding during installation, creating seamless bonds at joints. EPDM relies on adhesives or mechanical fasteners with specialized tape or liquid sealants for seam connections.

Performance comparison in Florida weather conditions

Florida’s climate presents unique challenges for flat roofing systems. Intense UV exposure, frequent thunderstorms, and hurricane-force winds test every aspect of roofing performance throughout the year.

TPO’s reflective white surface can reduce roof temperatures by up to 60 degrees compared to dark surfaces, according to jpcarrollroofing.com. This temperature reduction translates to significant energy savings, with some Florida building owners reporting 20-30% lower cooling costs after switching from dark roofing materials.

EPDM’s flexibility gives it an advantage during temperature fluctuations. The material remains pliable in both extreme heat and cooler winter conditions, reducing the risk of cracking or splitting. This flexibility becomes particularly important during Florida’s occasional cold fronts when temperatures can drop 40 degrees in a few hours.

| Feature | TPO | EPDM |

|---|---|---|

| UV Resistance | Excellent (reflective) | Excellent (absorbs/withstands) |

| Wind Uplift | Heat-welded seams | Adhesive/mechanical attachment |

| Hail Resistance | Good puncture resistance | Superior impact absorption |

| Hurricane Performance | Strong seam integrity | Proven flexibility |

Both materials handle Florida’s heavy rainfall effectively when properly installed. TPO’s heat-welded seams create watertight bonds that resist separation during severe weather. EPDM’s proven track record includes successful performance through decades of Florida hurricanes and tropical storms.

Energy Insight: White TPO roofs can reflect up to 87% of solar radiation, while black EPDM absorbs most heat but offers superior durability against physical damage from storms and debris.

Cost analysis and long-term value considerations

Initial installation costs represent just one part of the total investment in rubber roofing. Understanding the complete cost picture helps you evaluate which material provides better long-term value for your specific situation.

TPO installation typically ranges from $10-20 per square foot, including materials and labor. For a standard 1,700 square foot flat roof, expect total costs between $17,000-34,000. The material’s energy efficiency can offset higher installation costs through reduced cooling bills over time. For a comprehensive breakdown of pricing factors, review our guide on flat roof installation costs and options in Florida.

EPDM costs slightly more upfront, ranging from $12-26 per square foot. The same 1,700 square foot roof would cost $20,400-44,200 for complete installation. However, EPDM’s longer lifespan and lower maintenance requirements often justify the additional investment.

Maintenance costs differ significantly between these materials. TPO’s heat-welded seams require less frequent repairs, while EPDM’s adhesive seams may need attention every 10-15 years. However, EPDM repairs are often simpler and less expensive when they do occur.

Energy savings calculations show TPO providing greater long-term value in cooling-dominated climates. A typical Florida commercial building can save $2,000-5,000 annually in energy costs with reflective TPO compared to black EPDM, according to flatroofingflorida.com.

Installation requirements and maintenance expectations

Professional installation is crucial for both TPO and EPDM systems, but the processes differ in complexity and equipment requirements. Understanding these differences helps you plan your project timeline and budget accordingly.

TPO installation requires specialized heat-welding equipment and trained technicians. The process involves rolling out membrane sheets and using hot air welders to fuse seams together. This creates permanent, watertight bonds that are often stronger than the membrane itself. Installation typically takes 2-4 days for most residential and small commercial projects. For mobile home applications, TPO roofing offers specific advantages worth considering.

EPDM installation offers more flexibility in attachment methods. Contractors can use fully adhered, mechanically attached, or ballasted systems depending on building requirements. Seams are sealed using specialized tapes or liquid adhesives. The process is generally faster than TPO installation, often completing in 1-3 days.

Maintenance requirements favor TPO in terms of frequency but EPDM for simplicity. TPO roofs need regular cleaning to maintain reflectivity and occasional seam inspections. EPDM requires periodic seam maintenance but tolerates minor damage better than TPO.

Maintenance Tip: Both systems benefit from bi-annual professional inspections, especially before and after Florida’s hurricane season. Early detection of minor issues prevents costly emergency repairs during severe weather events.

Both materials can last their expected lifespans with proper maintenance. TPO typically requires replacement after 20-25 years, while EPDM can perform effectively for 25-30 years or more. The key is working with experienced contractors who understand Florida’s specific climate challenges and building code requirements.

Choosing between TPO and EPDM ultimately depends on your priorities regarding energy efficiency, upfront costs, and long-term maintenance preferences. TPO excels in energy savings and modern performance, while EPDM offers proven durability and cost-effectiveness. When comparing TPO against other materials like modified bitumen roofing systems, it’s important to evaluate all options to determine what flat roof is the best in Florida for your specific building. Both materials provide excellent protection for Florida flat roofs when properly installed and maintained by qualified professionals.