Single-Ply Roof Membrane Pros and Cons for Florida Properties

Posted 1.07.2026 | 7 Minute Read

Florida’s challenging climate demands exceptional flat roofing solutions. Single-ply roof membranes have emerged as a popular choice for both residential and commercial properties across the state. These rubber-based roofing systems offer a compelling combination of durability, energy efficiency, and cost-effectiveness that makes them particularly well-suited for Florida’s intense UV exposure and frequent storms.

Single-ply membranes can last 20-30 years in Florida’s climate when properly installed and maintained, making them a smart long-term investment for property owners.

If you’re considering a flat roof replacement, understanding the complete picture of single-ply membrane benefits and drawbacks will help you make an informed decision. This guide covers everything from material types to installation considerations, giving you the insights needed to determine if single-ply roofing is right for your property.

Understanding single-ply roof membranes

A single-ply roof membrane consists of a flexible sheet of synthetic material that covers your entire roof in one continuous layer. Unlike traditional built-up roofing systems that require multiple layers, these membranes are manufactured in large sheets and rolled out across your roof surface.

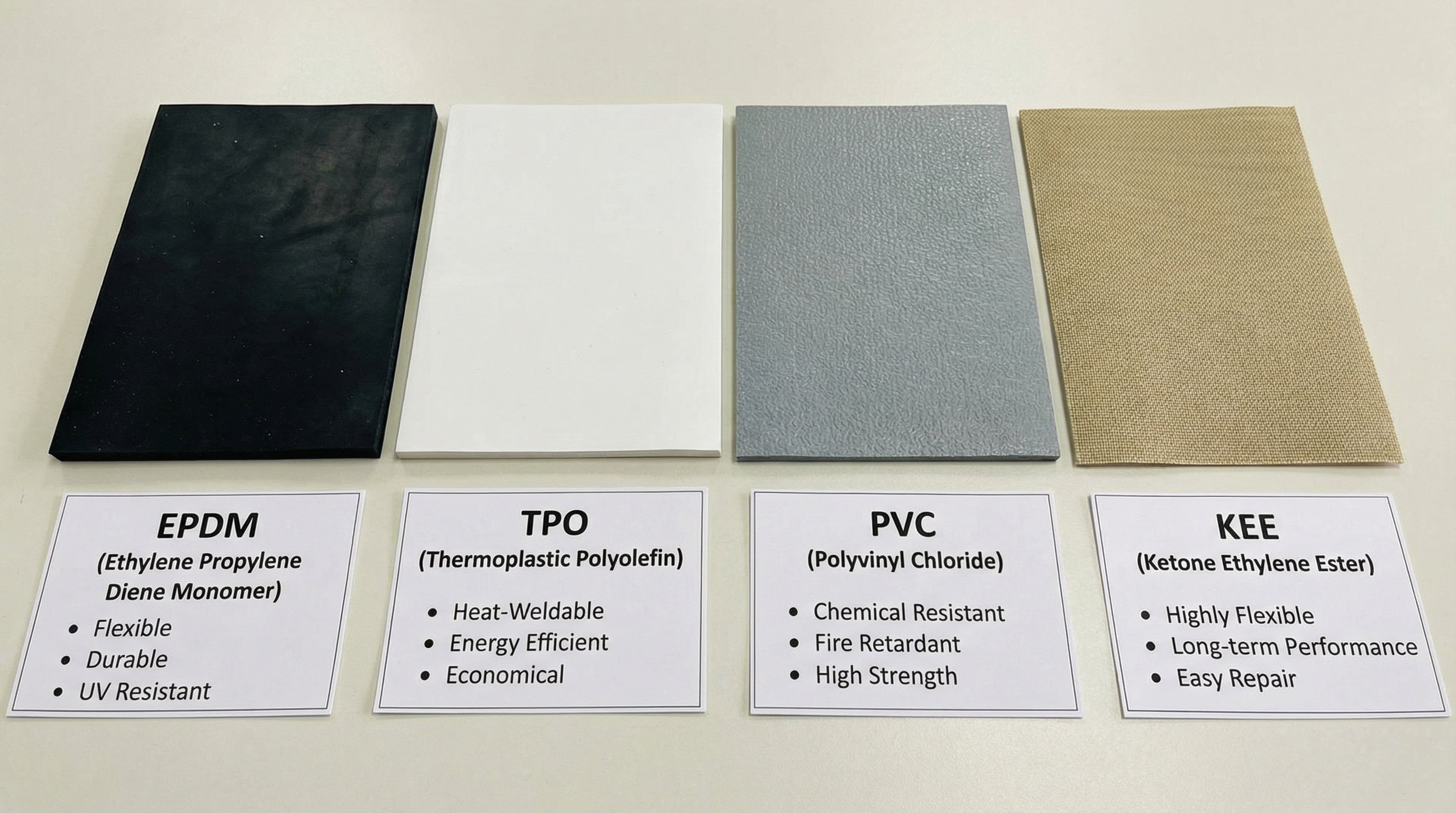

The most common single-ply materials include thermoplastic polyolefin (TPO), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM). Each material offers unique properties, but all share the fundamental advantage of creating a seamless, waterproof barrier when properly heat-welded or adhered.

Modern single-ply membranes incorporate advanced polymer technology that provides excellent resistance to UV radiation, temperature fluctuations, and chemical exposure. The installation process involves mechanically attaching or fully adhering the membrane to your roof deck, then heat-welding the seams to create watertight joints.

This roofing approach has gained significant traction since the 1960s, with continuous improvements in material formulation and installation techniques making single-ply systems increasingly reliable for Florida applications.

Major advantages of single-ply roofing systems

Single-ply membranes offer several compelling benefits that make them attractive for Florida property owners. The installation process is notably straightforward compared to multi-layer systems, which translates to lower labor costs and faster project completion. Most single-ply installations can be completed in a fraction of the time required for traditional built-up roofing.

Energy efficiency represents another significant advantage. White and light-colored single-ply membranes reflect substantial amounts of solar radiation, reducing cooling loads during Florida’s hot summers. This reflective property can lead to measurable reductions in energy bills, particularly for commercial buildings with large roof areas.

The durability of modern single-ply systems has improved dramatically over recent decades. Quality membranes resist punctures, tears, and chemical damage while maintaining flexibility through temperature changes. Heat-welded seams create bonds that are often stronger than the membrane material itself, providing excellent long-term water resistance.

Single-ply roofing installation typically costs 15-25% less than comparable multi-layer systems due to reduced labor requirements and faster installation times.

Maintenance requirements are generally minimal with single-ply systems. The smooth surface sheds debris easily and allows for straightforward inspection and repair when needed. Many manufacturers offer warranties extending 15-20 years, reflecting confidence in the material’s longevity.

Potential drawbacks and limitations

Despite their many advantages, single-ply membranes do have some limitations that property owners should consider. Seam integrity represents the most critical vulnerability in these systems. While heat-welded seams are initially very strong, Florida’s intense UV exposure and thermal cycling can cause gradual degradation over time.

The relatively thin profile of single-ply membranes makes them more susceptible to puncture damage from foot traffic, falling debris, or maintenance activities. Properties that require frequent roof access may need additional protection or alternative roofing solutions.

Installation quality plays a crucial role in system performance. Poor workmanship during membrane installation or seam welding can lead to premature failures that may not become apparent for several years. This makes contractor selection particularly important for single-ply projects.

Some single-ply materials, particularly TPO, have undergone significant chemical reformulations in recent years as manufacturers work to improve performance. While these changes generally represent improvements, the long-term track record of newer formulations is still being established.

Comparing single-ply membrane types

| Material | Average Cost | Lifespan | Energy Efficiency | Chemical Resistance |

|---|---|---|---|---|

| TPO | $4-8/sq ft | 20-25 years | Excellent | Good |

| PVC | $6-10/sq ft | 25-30 years | Very Good | Excellent |

| EPDM | $5-9/sq ft | 25-30 years | Good | Excellent |

Each single-ply material offers distinct characteristics that may make it more suitable for specific applications. TPO provides excellent value and energy efficiency, making it popular for commercial applications where cost control is important. The white surface reflects heat effectively and the material handles thermal movement well.

PVC membranes offer superior chemical resistance and fire performance, making them ideal for buildings that may be exposed to grease, oils, or other chemicals. Restaurants and industrial facilities often benefit from PVC’s enhanced durability in challenging environments.

EPDM, the original single-ply material, provides proven long-term performance with excellent weather resistance. While typically black, EPDM can be coated with reflective materials to improve energy efficiency. Its flexibility and proven track record make it a reliable choice for many applications.

The choice between materials often depends on specific building requirements, budget considerations, and local climate factors. When comparing TPO vs EPDM flat roofs, Florida’s intense UV exposure favors materials with proven solar resistance, while buildings near coastal areas may benefit from enhanced chemical resistance properties. For those weighing different options, understanding modified bitumen vs. TPO can also help inform your decision.

Making the right choice for your property requires careful consideration of both the advantages and limitations of single-ply roofing systems. While these membranes offer excellent value and performance for many Florida applications, success depends heavily on proper material selection, quality installation, and appropriate maintenance practices. To better understand your options, explore the best types of flat roofing materials for Florida and review flat roof installation costs and options. Working with experienced contractors who understand local conditions and manufacturer requirements will help ensure your single-ply roof delivers the expected performance and longevity for your investment.